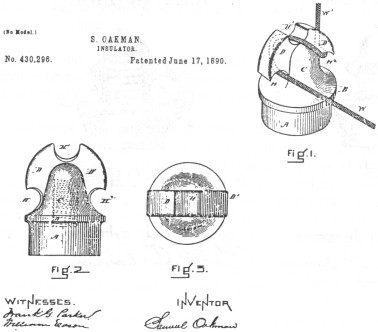

Samuel Oakman and Boston Insulator Production

by Bill Snell

Reprinted from "Crown Jewels of the Wire", November 1988, page 8

(Part II, Part I in September, 1988)

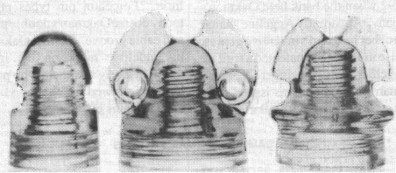

All American insulators have very distinctive threads: two rectangular

outlines appear on opposite sides of the pinhole and there are no threads in the

top quarter of the pinhole. Occasionally there will be a dot visible above the

rectangle, in the unthreaded portion. Several unembossed pieces have been

attributed to American because they have the characteristic American threads.

These include CD 105, 126.3, 134, and 134.4. There are also two pieces embossed

with only patent dates that have these threads. They are CD 156.1 embossed with

only PAT. SEPT. 13, 1881; and CD 156.2, embossed on the inner skirt PAT. OCT. 15, 1872.

One of the great mystery insulators: CD 156.2, embossed with the October

15, 1872 date and produced with

American-style threads |

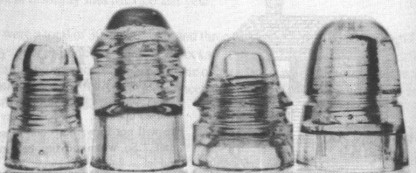

American Insulators: CD 105, 126.4, 134 and 145

The latter is an extremely scarce item

and may possibly be a prototype product made during the years just after Bay

State Glass Company ceased production. These pinhole lines have been attributed

to a collapsible plunger, which many believe to be the January 1, 1884, Edward

J. Murphy patent or the two October 7, 1884 patents granted to Lawrence Gray,

all of which were used by Gray's National Insulator Company in their production.

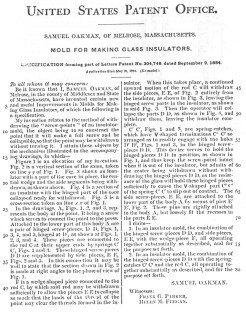

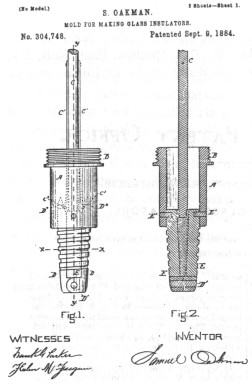

However, Oakman was granted a patent on September 9, 1884, covering a

collapsible plunger and in viewing the patent drawings, this is undoubtedly the

process used to produce the Americans. A CD 105 is even used in the

illustration. It seems unusual, though, that this date is not embossed on any

insulators. The close similarities between the patents, plus the fact that both

National and American were located in the same building in Boston and produced

rim embossed insulators seems far too extraordinary for coincidence. The main

link may be Edward Murphy, who is listed in the directories as a mold maker with

no company association. He probably made the molds for National, and possibly

American, Standard Insulator Company, and Oakman Manufacturing Company as well.

That might help explain the similarities between the insulators.

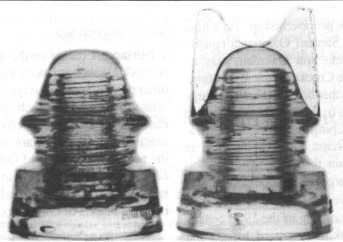

American Insulators: CD 156, 156.1 and 160.7

Unembossed Americans: CD 126.3, 134 and 134.4

American Insulator Company probably folded in late 1886 or 1887. For the

next few years, Samuel Oakman is listed in the Boston Directories as a dealer in

various bottles and insulators. Probably the CD 134 embossed OAKMAN PAT.

SEPT.13, 1881 was made at this time, using a reworked American mold. The

unembossed units with American threads may also have been made at this time.

In 1890 Oakman Manufacturing Company appears in the Boston Directory with an

address at 219 State Street, the address of Samuel Oakman's previous glass

dealership. The works was located on Mercer Street in South Boston. The

advertisements mention bottles, carboys, demijohns and insulators, and show an

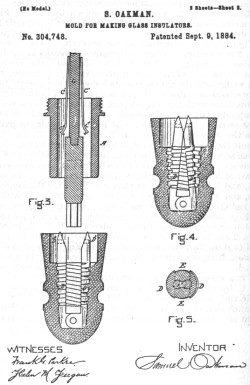

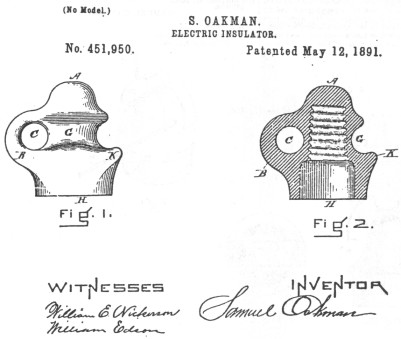

illustration of the CD 145 beehive. Also, during this period Oakman was granted

several more insulator patents. First was the August 19, 1890 patent for rings or

threads on the inside surface of the insulator skirt to help improve insulating

qualities. The June 15, 1890 patent for rings or threads on the inside surface

of the insulator skirt to help improve insulating qualities. The June 15, 1890

patent was issued for the familiar cable or saddle groove insulator still

popular today. Third was the May 12, 1891 patent for an insulator with one or

more eyes to secure the tie wire, which became known as the Columbia.

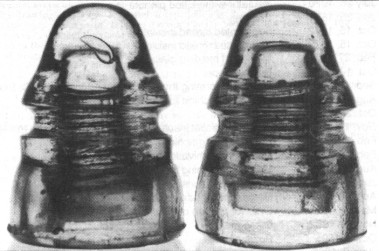

Oakman

Manufacturing Company produced mostly high voltage styles for the CD cables used

for streetcars and subways. Embossed Oakman, pieces are found in CD 140, 259,

263 and 269. Another probable product of the company is CD 144.5, embossed with

only the 1890 patent. Because the CD 134 was made in a reworked American mold,

and it is only embossed OAKMAN and not OAKMAN MFG. CO., it was probably made

earlier, in the years just after American folded.

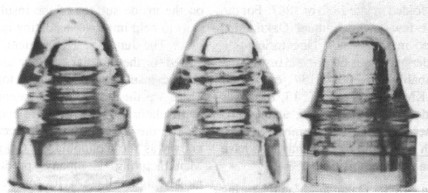

Oakman Manufacturing Company's two varieties of Jumbos: CD 140 and CD 269

More products of

Oakman Manufacturing: CD144.5. 263 and 259

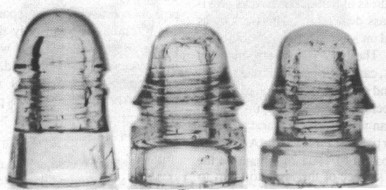

Two

varieties of Postals produced by American: CD 156 and CD 156.1

In 1892 the company name was changed to Oakman Glass Works and M.E.

Crocker, an influential Boston

banker, took proprietorship. As a note of interest, Samuel Oakman's cousin,

Richard Nickerson Oakman, was an officer of the Crocker Bank at that time. It's

possible that bank had called a large loan and was trying to recoup some of its

losses by keeping the company in operation, or perhaps it was being held in

trust. Within the year, Oakman was back in charge of the company and it remained

in operation until 1891. Also in 1891, according to the 1900 census records,

Oakman married his second wife, Angeline. Eliza had died sometime between 1881

and 1897, possibly in 1892 when the bank held Oakman's company. Apparently

Angeline shared some of her husband's inventive genius, because in 1902 they

patented a fruit jar lid together. On November 29, 1904, Oakman's last patent

was issued for a cable style insulator with a flaring skirt and an unusual top.

During his career in the glass business, Oakman was issued a great many other

patents for various types of bottle-related equipment, such as packing cases,

bottle molds and covers, splint machines, etc., which are included in the

accompanying list of Oakman patents. In all probability many of these items were

in production and may even be in the hands of collectors today.

Although a century has passed since most of Samuel Oakman's patents were

issued, insulators have changed very little. Porcelain pin types produced today

utilize Oakman's double petticoat and cable groove. Samuel Oakman left his

indelible mark on the insulator world in a way no others who preceded him or

followed him have. His influence remains even today.

|

SAMUEL OAK MAN PATENTS |

|

PAT# |

DATE ISSUED |

REGARDING |

88,066

|

Mar. 23,1869

|

Glass furnace

|

105,834

|

July 26, 1970

|

Insulator with slotted pinhole

|

117,320

|

July 25, 1871

|

Chimney

|

132,214

|

Oct. 15,1872

|

Segmented thread insulator

|

132,215

|

Oct. 15,1872

|

Segmented thread insulator

|

187,725

|

Feb. 27,1877

|

Method of molding glass

|

208,487

|

Oct. 17,1878

|

Bottle stopper

|

247,100

|

Sep. 13,1881

|

Method of forming threads (assigned to Edward C. Sherburne)

|

262,241

|

Aug. 8,1882

|

Weaving machine for bottle covers

|

287,049

|

Oct. 23,1883

|

Bottle cover

|

288,360

|

Nov. 13,1883

|

Double petticoat insulator (assigned to American Insulator

Co.)

|

292,942

|

Feb. 5,1884

|

Basket splint machine

|

14,674

|

Feb. 12,1884

|

Design of beehive insulator

|

304,021

|

Aug.26, 1884

|

Method of forming threads

|

430,296

|

June 17,1890

|

Saddle groove insulator

|

434,879

|

Aug.19, 1890

|

Rings or threads on skirt

|

451,950

|

May 12,1891

|

Eyes for tie wire on insulator

|

486,182

|

Nov.15, 1892

|

Glass mold

|

547,936

|

Oct. 5,1895

|

Bottle stopper

|

561,912

|

June 9,1896

|

Packing case for bottles

|

693,056

|

Feb. 11,1902

|

Fruit jar lid (assigned 1/2 to Angeline C. Oakman)

|

755,056

|

Nov. 29,1904

|

Insulator

|

A very special thanks to several people who made this article possible. Dick

Bowman, Ray Klingensmith, Joe Maurath, Tom Moulton, Paul Snell, N.R. Woodward,

the Boston Public Library, the Rochester Public Library and the United States

Chamber of Commerce.

Medium Image (128 Kb)

Large Image (261 Kb)

Large Image (79 Kb)

Large Image (92 Kb)

Medium Image (85 Kb)

Large Image (178 Kb)

Large Image (54 Kb)

Medium Image (69 Kb)

Large Image (167 Kb)

Large Image (61 Kb)

|